The genesis of Neoteric Hovercraft, Inc. occurred in July 1959 when the company's founder, Chris Fitzgerald, watched a television program about the British Saunders Roe Nautical Model One (SRN1) hovercraft crossing the English Channel. He was inspired by the prospect of being able to fly “safely”, albeit close to the ground, without having to be immensely rich like an aviator. Even though Chris was only 15 years old at the time, he began pondering the idea of inventing a smaller version of hovercraft, and marketing it to the world for a vast number of applications ranging from recreation to rescue.

At the time of the SRN1's crossing, Chris' father, Gerald, and his two uncles Bill and Jack were the Fitzgeralds’ third generation to own and run the family sheet metal business, which started when the family arrived in Australia from Ireland during the 1850s Ballarat Gold Rush in Victoria. They supplied billys, buckets, pans, funnels, and many other sheet metal items needed on the gold field. When the gold source was eventually depleted, the Fitzgeralds moved to Melbourne where they started W. Fitzgerald and Sons in a half basement on Elizabeth Street, causing them to be known as the "Underground Tinsmiths". By the time of World War I, the family had become so prosperous that they had to expand to two locations, one at the Haymarket in a building that still stands in the alley-way behind the Melbourne Motor Inn, (demolished during 2022) and one on Swanston Street that later became Melbourne University's Child Minding Center. In 1972, W. Fitzgerald and Sons was sold to a private individual.

The Fitzgerald independent spirit so influenced Chris that in 1956, when he was 12 years old, he was already in the business of creating and selling model aircraft. At age 14 he joined the Royal Australian Air Force Air Training Corps and, at the same time, became the youngest member of the Australian Experimental Aircraft Association (then known as the Ultralight Aircraft Association of Australia), seeing both affiliations as an introduction to the world of flight. When, at age 15, he started working on his own hovercraft designs, Chris attracted the interest of the Aeronautical Research Laboratories in Melbourne and they soon employed him as a technical assistant. Work was done on various hovercraft projects such as crevasse jumping and ejector driven recirculation annular jets. During this time, Chris served as a Technical Assistant to Dr. David Warren, who was then developing the world's first "Black Box" flight recorder. (Early boxes were not black, but bright orange.) He was also an assistant to Bill Howard, Dennis Frith, Murdock Culley, Alan Cox, and others.

|

| |

|

|

|

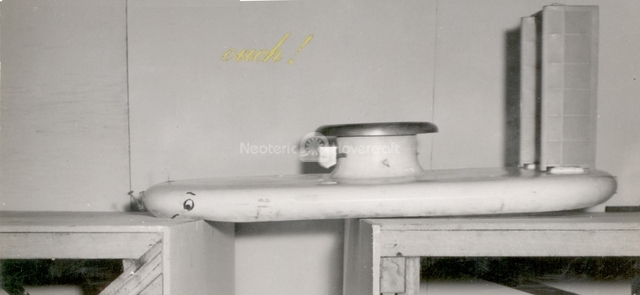

| Measuring over water drag on a statically hovering man-carrying hovercraft. This plenum chamber hovercraft used a 2-cycle 3½ HP lawn mower engine for lift. |

|

|

Hovercraft experiments conducted at the Aeronautical Research Laboratory in Melbourne included crevasse jumping tests, as Australia had an active interest in Arctic transportation. This experiment consisted of a 60-foot long platform 8 feet wide and 4 feet off the hangar floor. Scale model hovercraft were catapulted along the center at various speeds and adjustable crevasse widths. At speed, the model could jump a crevasse of width almost 3/4 the length of the craft. Notice these tests were conducted on models that utilized the annular jet principle, before the days of hovercraft skirts. |

|

|

| |

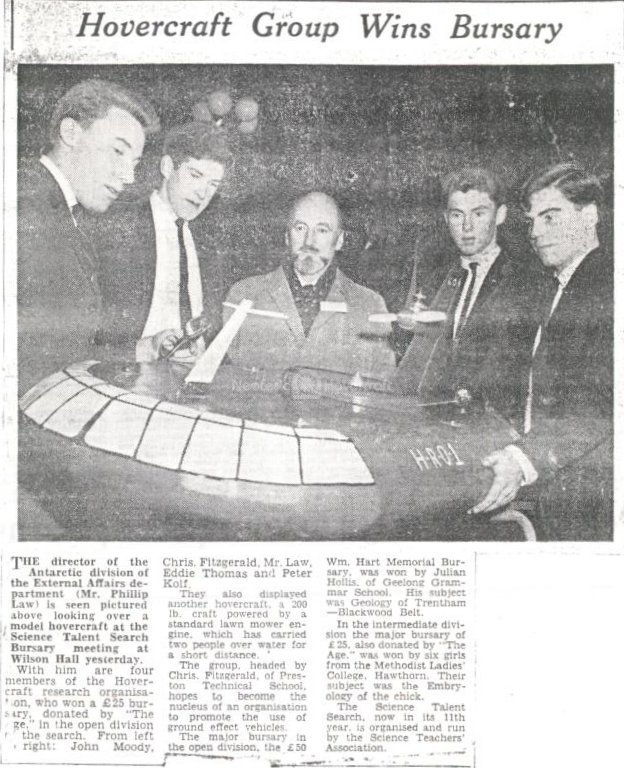

In the early 1960s, while in the Royal Australian Air Force Air Training Corps, Chris found a ready supply of material with which to develop his hovercraft designs, and formed a club/business relationship with several fellow Cadets to help expedite his goal of creating a functional, personal-sized hovercraft. Together, Chris, Robert Wilson, Peter Kolf, and Alan Schwartz, as well as other members from outside the Air Training Corps — Eddy Thomas, Arthur Boyd, Bernard Sutcher, Laurie Fair and Sam Ciliauro - established the Hovercraft Research Organization. Their home base was located in a suburb of Melbourne at the Brunswick Boys’ Club, and the partners operated a Jazz Club to raise funds for their hovercraft research.

As an interesting side note, during this time they hired a new band, known as The Seekers, to perform at the Jazz Club. The very next week, The Seekers were called to England to perform the title song of the 1966 British film Georgy Girl, starring Lynn Redgrave. The title song became a hit single and was nominated for an Academy Award for Best Original Song. The Seekers were the first Australian popular music group to achieve significant chart and sales success in the United Kingdom and the United States.

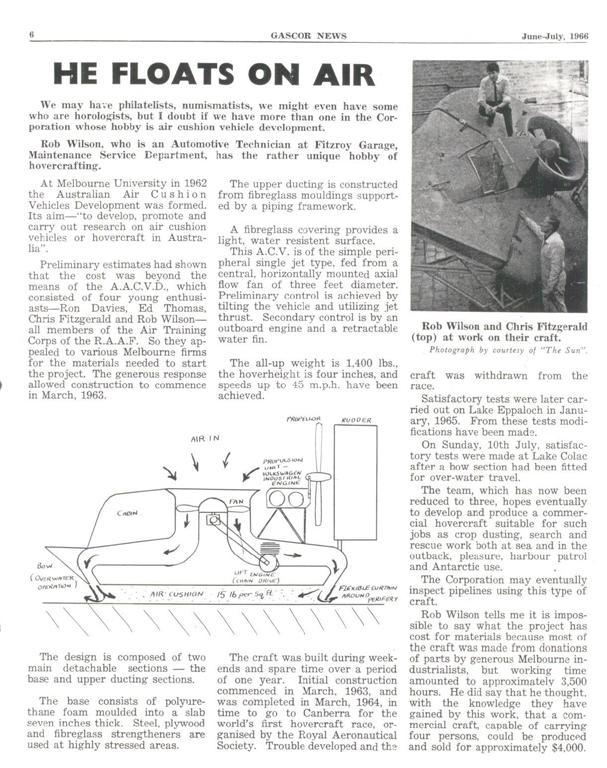

In the mid-1960s, the Hovercraft Research Organization changed its name to Australian Air Cushion Vehicles Development. More than 50 Melbourne businesses agreed to donate materials to aid the group in the building of an experimental man-carrying model. Considered an extracurricular activity at the Air training Corps, the Cadet members worked after hours at the facility, and then at various backyard sheds and garages, crafting many different models and test rigs. Most valuable to the project at this time was Robert Wilson, who is still involved today with design and product development at Neoteric Hovercraft, Inc. David Atkins, who was introduced to the team by Arthur Boyd, is still the company’s aesthetic and ergonomic design engineer. Other members have gone on to such professions as Qantas Performance Engineer, Royal Australian Navy Engineer, Professor of Naval Architecture, General Motors Australia Design Engineer and Pfizer Australia Marketing Manager.

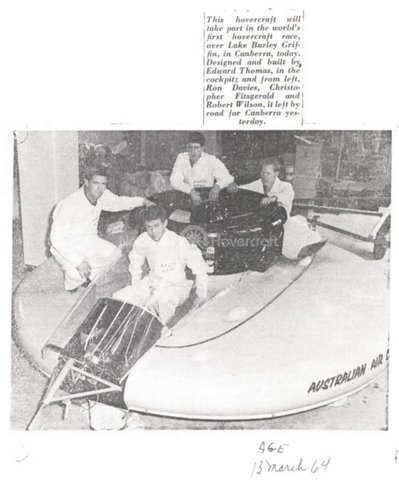

Construction of the hovercraft that introduced practical engineering design concepts took place at Melbourne University’s Mechanical Engineering School from 1962 to 1964; this craft was entered in the World’s First Hovercraft Race on March 14, 1964 in Canberra, Australia, the official name for this event was The World’s First Ground Effect Machine Race. The Canberra Branch of the Royal Aeronautical Society organized this event. Much to the chagrin of the Melbourne University’s Chancellor, it made its first run on his back lawn during an early Sunday morning in the early part of 1964. After participating in the first race, the group moved into W. Fitzgerald & Sons factory on Swanston Street in Melbourne, where development continued.

By 1968 Chris had left Aeronautical Research Laboratories and joined the family business along with Robert Wilson. Involvement at W. Fitzgerald & Sons lasted until 1969 when Robert Wilson resumed his engineering education and Chris Fitzgerald won a Rotary Club scholarship to study aeronautical engineering in the UK at the Farnborough Technical School and to work as an intern at British Hovercraft Corporation (formerly Saunders Roe), and then to travel the world to survey the latest in hovercraft technology.

In 1973, Australian Air Cushion Vehicles Development was renamed and incorporated as Neoteric Engineering Affiliates Pty Ltd. In 1975, Chris moved to the United States and incorporated Neoteric, Inc. in Indiana. It also traded as Neoteric USA Inc. and much later became Neoteric Hovercraft, Inc.

| 1963-1972 Rob Wilson, President, Neoteric Engineering Affiliates, Pty. Ltd, Australia; Technical Director, Neoteric Hovercraft, Inc. compiled the History of AACVD's developments. Rob Wilson graduated from the Footscray Institute of Technology in 1973. For more information about Rob Wilson's story, see this link. AACVD5 (version 5) was the first full sized man carrying hovercraft constructed by Neoteric, then known as Australian Air Cushion Vehicles Development. Many models and test rigs had been made and run in the years dating back to 1960, so a significant knowledge of the air cushion principle was available before AACVD5 was built. However, little was known about the construction of a full sized craft with its complex and inherent engine, transmission and operational environment problems - and nothing was known about flexible skirts. The learning curve was steep with many mistakes being made. It has been estimated that for every hour of the machine’s recorded total of 91 hours and 16 minutes of lift engine running time, 218 hours of repair, modification and maintenance was required. That’s nearly 20,000 hours of labor or about 2,000 hours per year over the life of the craft - not a minor effort for a small group of part timers. See this link for extensive detail about AACVD development's history. |