October 1987 First engine run of 2 Fuji 2-cycle engines.

November 1997 - Static tests at Hastings test facility gave a thrust of 170 lbs but erratic starboard. engine performance produced a synchronous beating vibration.

December 1987 - Hastings mud flat runs. Marginal stability due to speed variations on one engine. January 1988- Hastings mudflats. Salt bridging on engine cut out, high vibration and high cabin

noise.

January 1988 - Hoverclub event at Kangaroo Lake, Victoria. Rough water and troublesome engine speed variations. Reverse buckets limited effectiveness due to their small size.

March 1988 Hastings overwater run. Larger buckets fitted and were more effective.

August 1988 - Hastings run. Port engine speed drops and need for windscreen wiper to aid visibility

over water.

Run time on Fuji engines 8 hours and 20 minutes.

November 1988 - Because of the difficulty of synchronizing the engine speed of the Fuji motors and the internal noise and vibrations it was decided to fit a single engine to drive both fans. The engine selected was a Fuji Subaru EA 82 unit developing 85 hp at 5,000 rpm.

February 1989 - Hastings run. Larger radiator fitted and engine water temperature 90 degrees C.

June 1990 Hastings rally. Wet and windy. Collision accident with UH19 craft, minimal damage.

December 1990 - Spray skirt fitted. Hastings run showed reduced spray but increased skirt drag in

January 1989 - Hastings static test. Over 218 lb thrust and much reduced noise and vibration.

January 1989 - Elwood beach. Rough water, estimated 1 metre waves and 20 mph wind. Several successful runs but sand found its way into rudder bearings and seat mechanism causing binding.

January 1989 National rally, lake Cargelligo NSW. High engine water temperature, 110-115 degree C, demonstrated the need for a larger radiator.

waves.

March 1991-Hastings to Blind Bight run and return. 1-1/2 ft waves on return journey.

April 1991- Hastings to French Island run, 1 ft waves on choppy water. Towing disabled hovercraft on the return trip caused excessive spray resulting in spark plug salt water shorting and engine misfiring.

November 1991 - Hastings run with an experimental hovering windscreen wiper installed but not enough spray to test effectiveness. Spray skirt observed to be working well.

August 1992 - Hastings rally. Difficult control in 25 knot winds. Bucket cable frozen with salt. Maximum thrust 190 lbs at 4,050 engine rpm.

March 1993 - Lake Eildon rally. Engine rpm low due to salt corrosion on carburettor restricting throttle opening. Oil spilling from engine crankcase vents, higher vent outlets needed.

August 1993-A compression test on engine cylinder revealed only 65 psi so maintenance required.

November 1993 Major engine maintenance including valve grind, replace lifter, replace port camshaft with stronger version. Fan pitch was reduced to allow engine to reach its peak power rpm.

Total engine run time 27 hours

December 1993 - Hastings rally. Anemometer fitted, experimental screen wiper removed. Wind 20 knots steady, 30 knots gusts. Maximum engine speed 5,000 rpm.

February 1994 Blind Bight rally. Cruise speed 30 knots at 4,000 rpm, pay load 500 lbs.

February 1995 Hastings run. One half metre wave height.

April 1995 Video shoot at Hastings.

February 1996 Blind Bight rally, cruise from Hastings.

August 1996 Hastings run for Dr. Lawry. Ignition shorting due to poor spark plug boot seals.

May 1997 - Replace seized rudder cable, clean binding throttle cables, reseal ignition, replace 2 jupes and repair hull damage.

May 1997 - Hastings rally. Cruise at 30 knots. Skirt tuck under on flat, calm water but no hull contact due to jupe stability skirt.

October 1997 - Hastings run for Don Grey from Tasmania (one of the original N2 builders using N2 plans). 20 knots of wind, gusting to 30 knots.

April 2000- Check run at Hastings. Minor oil leak from sump, may be due to pin hole corrosion.

April 2000- Hastings water and mud flat runs. Jupes did not fully deploy for some run time resulting in marginal stability.

After jupe full deployment stability restored.

The total engine run time recorded by hour meter was 38 hours and 50 minutes. Subtracting the Fuji engine run time leaves about 30 hours total hovering on the Subaru engine. The hour meter was rigged via a cushion pressure switch so that only hovering time on cushion was recorded. In conclusion maintenance is a significant factor in salt water operations, much more so than when only fresh water is encountered.

|

| |

|

|

|

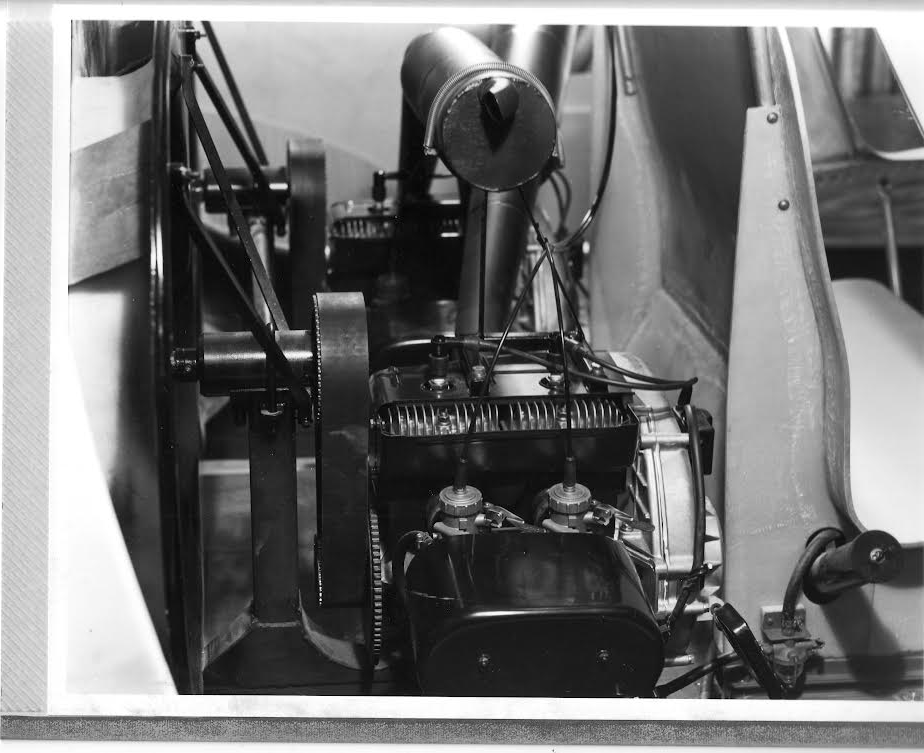

| This shows the installation of two 50HP Fuji Subaru Snowmobile engines. With this arrangement, it was difficult to synchronize engine speeds. |

|

|

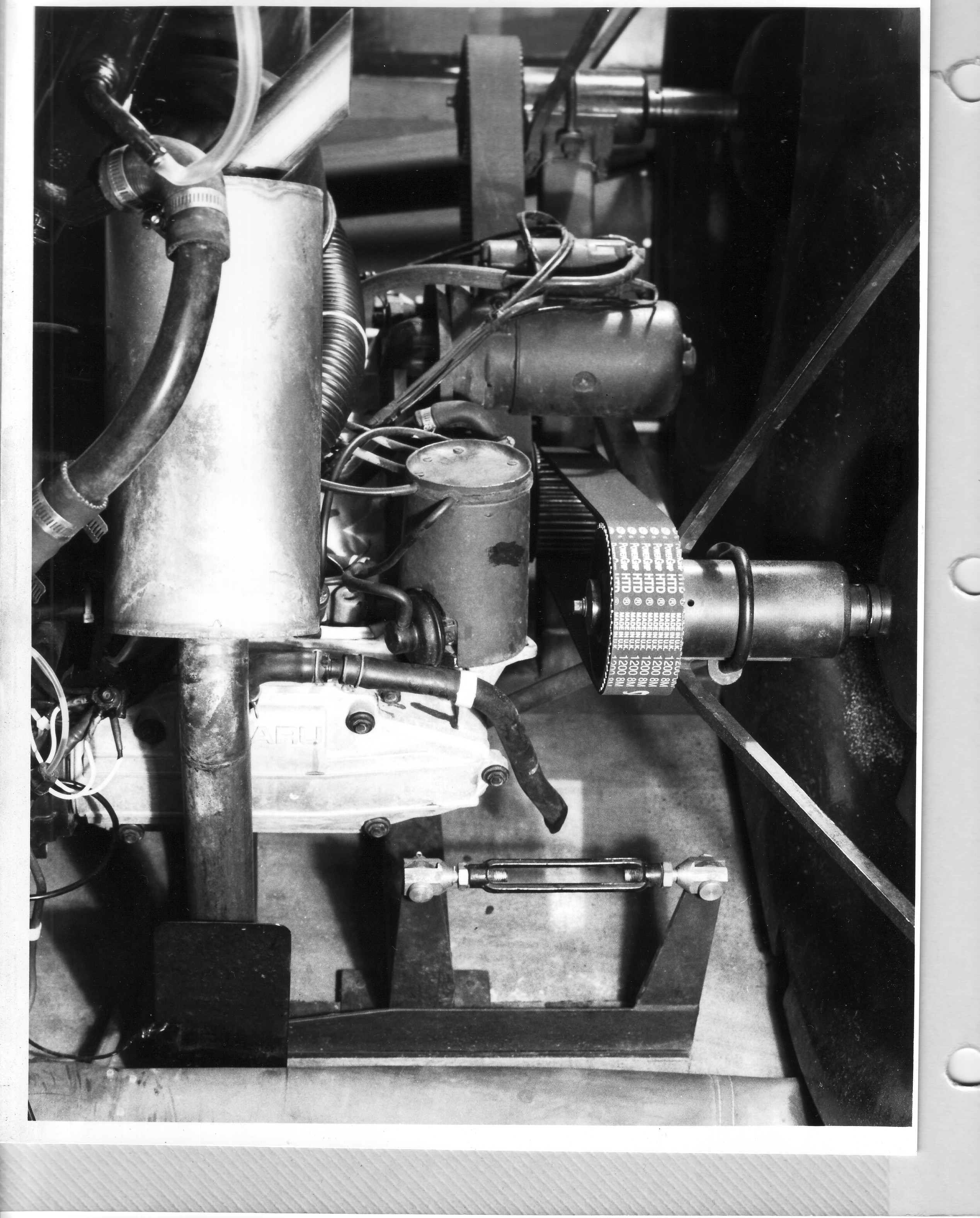

Here is the replacement 82HP EA82 Fuji Subaru 4 cyclinder engine. This proved more reliable but heavier. |

|

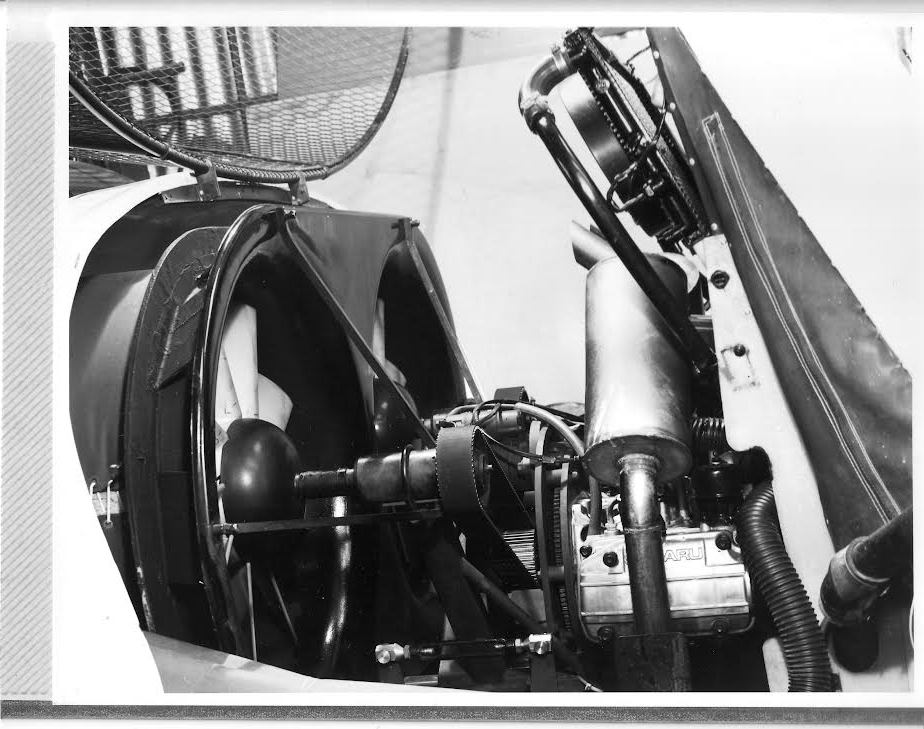

EA82 Subaru Engine Installation in Neova 4 showing fan belt drive and stainless steel exhaust. |